Cleaning Technologies Group (CTG) develops a variety of cleaning solutions that are well suited to meet the challenges of automotive component cleaning. Our capability range extends from heavy soil removal applications such as remanufacturing to precision particle cleaning of electronic and fluid system components. We regularly design and manufacture system solutions to help our customers meet ISO 16232 and VDA 19.1 driven technical cleanliness specifications.

Ransohoff Offers Multiple Solutions

Ransohoff offers excellent cleaning performance for applications in the automotive parts industry. Our energy efficient LeanVeyor Conveyor Washer is engineered for lean manufacturing. It reduces floor space requirements while providing exceptional cleaning and drying performance. The design of this conveyor washer also offers quick and efficient access for servicing.

When it comes to rotary basket washers, the Lean Jet® systems are popular for automotive parts cleaning applications:

RB-2 Immersion Cleaning System

Processes two (2) baskets of parts per cycle, up to twenty (20) baskets per hour.

RB-8 Immersion Cleaning System

Processes eight (8) baskets of parts per cycle, up to eighty (80) baskets per hour.

The LeanJet RB-2 Automated Immersion Cleaning System features the latest Siemens S7-1200 programmable controller and operator interface screen. This controls platform boosts system flexibility for automation integration, process control and data logging while offering an intuitive user interface.

All of the Ransohoff LeanJet products are available with customer specific basket designs to accommodate larger parts.

The patent pending Rotosonic™ Ultrasonic Cleaning System is an automated cleaning system that delivers maximum cleaning efficiency using high-pressure spray, part rotation, and ultrasonic energy. The Rotosonic cleans heavily soiled automotive parts in one piece of equipment, eliminating the need to purchase a spray cabinet and an ultrasonic machine individually. Compact in size, the Rotosonic provides versatility with the ability to perform either a single process or both, whatever is required for the application. This automotive parts cleaning solution also reduces or eliminates labor needs and safety risks of moving parts from washer to washer.

Blackstone-Ney Ultrasonic Solutions

The Blackstone-NEY AgiSonic® ultrasonic cleaning system is designed to wash heavy-duty components, like automotive parts, with vertical parts agitation. This system is available in three standard sizes, each incorporating an air powered agitation platform that facilitates loading, unloading, and agitates parts with a 6" stroke up to 15 times per minute.

The Blackstone-NEY Robosonic™ ultrasonic cleaning system is an automated tank to tank cleaning platform leveraging the use of 6-axis robotic handling to maximize throughput and provide footprint flexibility. Additionally, the use of the advanced robotic handling allows for functionality such as basket and part manipulation. This can assist in draining the parts or baskets between tanks, or avoiding air traps or splashing during part or basket placement.

A popular choice for tool rooms, racing shops, and remanufacturing businesses, GMC ultrasonic cleaning systems are available from stock in two standard sizes. The larger can accommodate parts with one dimension up to 35 inches and weighing up to 125 pounds. Both units are entirely self-contained, are supported on casters and operate from commonly available power supplies making them easy to move where needed.

The Aquarius Series of ultrasonic cleaning systems is another product group that offers advantages to the automotive industry, specifically for the production of electric cars. All ADAS (advanced driver assist systems) incorporate electronic sensor technologies. The assembly of these sensors must be done in a clean room to avoid having particulate obscure optical sensors and to avoid metal particles on PCBAs and other components. The die-cast and machined housings for these assemblies must be precision cleaned. Tier 1 and Tier 2 suppliers, such as PCBA manufacturers and die casting manufacturers will benefit from Lean Aquarius cleaning technologies for these sensitive components.

Applications:

- Engine Heads & Blocks (Download Case Study)

- Differential Case (Download Case Study)

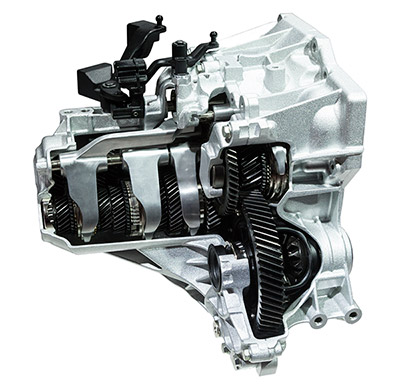

- Gearing (Download Case Study)

- Pre-Laser Welding (Download Case Study)

- Shafts (Download Case Study)

- Diesel Injectors

- Various Engine Components

- Torque Converters

- Input / Output Shafts (Download Case Study)

- Transmission Cases / Components

- Pinion Gears (Download Case Study)

- Brake Systems

- Steering (Download Case Study)

- A/C Systems

- Cylinder Heads (Download Case Study)

- Engine Dampener Components (Download Case Study)

English

English Spanish

Spanish Chinese

Chinese Canada

Canada Mexico

Mexico United Kingdom

United Kingdom