Cleaning Technologies Group, a world leader in providing cleaning and waste minimization technologies, will introduce a host of advanced cleaning solutions at the IMTS 2014 in Chicago, Illinois September 8 - 13, 2014. Visitors to Cleaning Technologies Group Booth E-5663 will be introduced to a number of new products, technologies and services. Among the new technologies exhibited at the show will be:

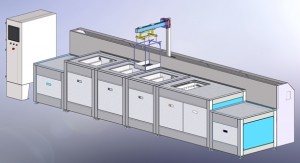

The New Blackstone~NEY Ultrasonics Modular Aquarius® Cleaning System is an innovation in aqueous parts cleaning, offering a modular plug & play configuration Multi-Tank Cleaning System. The Modular Aquarius is characterized by individual modules that can easily be integrated together to offer maximum flexibility to the end user. Standard wash and rinse stages can be mated to provide exactly the cleaning system required for today’s application. The Modular Aquarius comes standard with three frequencies 40, 72, 104 kHz in each tank, Siemens controller, automated hoist transfer system and much more. Additional modules can be added at any time allowing for future expandability.

AgiSonic® 4000 Ultrasonic Parts Washer Cleaning System also known as the "WashMaster & GMC Series Plus™", this robust line of ultrasonic cleaning systems designed for heavy duty parts washing with vertical parts agitation, and up to 21 watts per gallon/5.4 watts per liter of 40 kHz ultrasonics.

The AgiSonic parts washer is so versatile; it can be found operating in the harshest industrial environment and even in the most demanding medical clean rooms.

PROHT Sonic Tank also known as the "Benchtop Series" is an entry-level ultrasonic cleaning system made of all stainless steel construction. Available in various sizes and intended to sit easily on a workbench or as a drop-in, these parts washers offer the same cleaning capabilities as the more elaborate models but at a lower price. They are great for cleaning small parts on an intermittent to semi-production basis but are not recommended for high volume cleaning. These tanks are available for use with single or multi-frequency generators.

The New Lean-Jet® RT-18 robotically tended cellular parts washer. Ransohoff has developed an innovative, patented drive system that adds an entirely new level of flexibility to this already extremely effective cellular design. While the previous generation did provide planetary part rotation at each processing station, the new design allows for each individual table to be programed to rotate a part in multiple directions, at varying speeds, or to pause and position a part for dedicated spaying or probing of critical holes or difficult to address areas. As table position is tracked throughout the cycle and parts are positively located at the load and unload station, this design is a perfect match for a robotically tended manufacturing cell.

The New Lean-Jet® RT-18 robotically tended cellular parts washer. Ransohoff has developed an innovative, patented drive system that adds an entirely new level of flexibility to this already extremely effective cellular design. While the previous generation did provide planetary part rotation at each processing station, the new design allows for each individual table to be programed to rotate a part in multiple directions, at varying speeds, or to pause and position a part for dedicated spaying or probing of critical holes or difficult to address areas. As table position is tracked throughout the cycle and parts are positively located at the load and unload station, this design is a perfect match for a robotically tended manufacturing cell.

This cellular washer is available with various configurations offering not only the ability to wash and dry your parts but also rinsing or part cooling if necessary. The RT-18 accommodates a wide range of part sizes, weights and geometries and will produce up to one part, or table of parts, every 30 seconds depending on the application. The new generation Lean-Jet RT-18 is available with a Siemens PLC and HMI package.

• Lean-Jet® RB-8 Immersion Cleaning System processes eight (8) baskets of parts per cycle, up to eighty (80) baskets per hour. The Lean-Jet RB-8 parts washer cleans using our patented washing and rinsing process of agitation, sprays impingement, hydraulic purging through immersion and rotation, and heated blow-off drying. Our patented "triple action" batch cleaning process was developed specifically to process a broad range of challenging parts, especially those with internal bores and passages. In addition, the Lean-Jet RB 8 is designed to be equipped with ultrasonics if required.

At the show we will have technical experts available to explain our technologies in more depth and provide suggestions to our customers to improve their cleaning processes.

To schedule your visit go to www.ctgclean.com/events

- Log in to post comments

English

English Spanish

Spanish Chinese

Chinese Canada

Canada Mexico

Mexico United Kingdom

United Kingdom