As a world leader in the development of cleaning and waste minimization technologies, Cleaning Technologies Group is proud of our Ransohoff Division. For decades, the Ransohoff name has been known for dependable and innovative aqueous parts washers. We are excited to announce that Ransohoff will be introducing a host of advanced cleaning solutions at two important industry events in October.

Wisconsin Manufacturing & Technology Show 2023

Ransohoff will be exhibiting in Booth #1023 at the Wisconsin Manufacturing & Technology Show (WIMTS). This year’s event will be taking place October 3-5, 2023, in West Allis, Wisconsin.

WIMTS is the industry-leading Midwest manufacturing trade show–from additive manufacturing to robotics, machining centers to welding, tooling and fabricating equipment and many more technologies in between. This year’s event will feature over 200 exhibitors and is expected to attract over 3,500 attendees.

Cleaning Technologies Group (CTG), a world leader in providing cleaning and waste minimization technologies is proud to participate in the Eastec 2023 in West Springfield, Massachusetts May 16 - 18, 2023.

Visitors to Cleaning Technologies Group Booth #3135 will get a first-hand look at our new products, and also learn about our technologies and services. Some of the innovative systems exhibited at the show include:

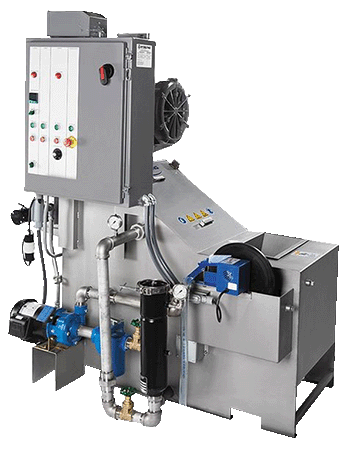

LeanJet® RB-1 Cleaning System

This system uses a patented washing and rinsing process of agitation, spray impingement, hydraulic purging through immersion and rotation, ultrasonics, and heated blow-off drying. The patented "triple action" batch cleaning process was developed specifically to process a broad range of challenging parts, especially those with internal bores and passages and complex geometries, making this system capable of meeting critical cleaning expectations.

The new LeanJet RB-1 parts washer also features the latest Siemens programmable controller and operator interface screen. This controls platform boosts system flexibility for automation integration, process control and data logging while offering an intuitive user interface. The new RB-1 has many enhancements for easy maintenance such as larger access doors, larger tank access lids, bolt-on air knives and more. The new RB-1 has a small footprint of 4ft. wide x 7ft. deep x 6.6 ft. height.

We’re happy to announce that CTG is now on Instagram. In today's fast-paced world, social media has become an indispensable tool for businesses like ours to expand their reach and connect with their audience. Among the various social media platforms available, Instagram has emerged as a powerhouse for businesses looking to boost their online presence. With over one billion monthly active users, Instagram offers a vast pool of potential customers to interact with.

Cleaning Technologies Group is excited to be an exhibitor at the 2023 Precision Machining Technology Show, the must-attend event for users of precision machining equipment and services related to machine tools, cutting tools, work handling, materials, parts cleaning, and more.

As a world leader in providing cleaning and waste minimization technologies, we will introduce a host of advanced cleaning solutions at the show, which will take place in Cleveland Ohio, April 18 - 20, 2023. Visitors to Cleaning Technologies Group exhibit, located in Booth #7092, will be introduced to a number of new products, technologies and services. Among the new technologies exhibited at the show will be:

January 2023 – Cincinnati, OH

Blackstone-NEY Ultrasonics, a leading supplier of precision ultrasonic technologies, is pleased to announce the Company has leased a 21,000 ft/sq high bay facility in Falconer, NY.

The lease of the new building will increase manufacturing capacity and allow for efficient workflow on medium to large precision ultrasonic cleaning lines.

Eric Kenney, President of Blackstone-NEY Ultrasonics stated that “Our business has expanded considerably over the past few years, especially with engineered to application precision cleaning machinery. This move will

Blackstone-NEY Ultrasonics, a world leader in providing cleaning and waste minimization technologies, will introduce a host of advanced cleaning solutions at the MD&M West 2023 in Anaheim, California February 7 – 9. 2023. Visitors to Blackstone-NEY Ultrasonics Booth #1533 will be introduced several new products, technologies, and services. Among the new technologies exhibited at the show will be:

Aquarius: Combining ultrasonic cleaning with rinsing, drying and other processing steps in a unitized cleaning console helps assure process integrity. The addition of an automated robotic transfer, environmental enclosure, and DI water systems increases cleanliness levels and provides process consistency while significantly reducing the labor required for parts cleaning.

Cleaning Technologies Group is excited to announce that Unitech Washing Systems will be exhibiting at PACK EXPO International, the company’s first U.S. trade show since the launch of the company’s new website. CTG has been a proud partner of Unitech since August of 2020, distributing specialty washers in the U.S. for the food and beverage industry.

The PACK EXPO International show will be taking place at McCormick Place in Chicago, IL, October 23rd -26th, 2022. Featuring packaging and processing solutions as well as educational sessions and networking opportunities, PACK EXPO International will be the industry’s most comprehensive event. This global show features the industry’s largest showcase of technology, including many product launches for more than 40 vertical industry sectors.

Unitech’s exhibit in Booth LU-7153 will include the Compact Traywasher with optional overhead feed for one man operation, the extremely versatile 1200 Series Industrial Pan Washer, as well as other compact boot washers and hygiene gates, used for personnel flow into food factories.

Ransohoff is proud to offer the Mini Parts Washer. This compact inclined conveyorized cleaning system is designed for cleaning small parts produced in continuous production. This productivity enhancing system is specifically targeted for point of manufacture cleaning. It is ideally suited for cleaning small parts such as screw machine products, stampings, and bearings.

MPW Standard Features

- Available in 6” and 12” belt widths

- Ideal for cleaning small parts

- Stainless steel construction for long life

- Automatic loading, cleaning, and unloading

- Small footprint, ideal for work cell applications

- Portable with forklift pockets and optional casters

- CE compliant

There is also an optional heated blowoff for enhanced drying feature available for field retrofit. Designed by Stoeltng and manufactured by Ransohoff, the Mini Parts Washer has a footprint of less than nine square feet, making it ideal for work cell applications.

MPW Cleaning Cycle

Parts drop into agitated solution

Oil skimmer removes floating petroleum-based waste oils with coalescer option.

Ransohoff will introduce a host of advanced cleaning solutions at the IMTS 2022 in Chicago, Illinois, September 12 - 17, 2022. Visitors to the Cleaning Technologies Group Booth #338774 will be introduced to several new products, technologies, and services. Among the new technologies exhibited at the show will be:

Lean-Jet RB-2: This Aqueous Immersion Cleaning System uses a triple-action washing and rinsing process consisting of agitation, spray impingement, hydraulic purging through immersion and rotation, ultrasonics, and heated blow-off drying. The triple-action batch cleaning process was specifically developed to process a broad range of challenging parts, especially those with internal bores, passages and complex geometries, making this system capable of meeting critical cleaning expectations. The LeanJet RB-2 offers an automated basket loading option that will be on display.

LeanVeyor: The LV conveyor parts washing system is engineered for lean manufacturing, while reducing floor space requirements and providing exceptional cleaning and drying performance. We use a common-sense approach to component choice and placement for quick and efficient service and access. All stages are insulated and compartmentalized with individually adjustable exhaust dampers, reducing system heat loss.

Blackstone-NEY Ultrasonics will introduce a host of advanced cleaning solutions at the IMTS 2022 show in Chicago, IL September 12 - 17, 2022. Visitors to the Cleaning Technologies Group Booth #338744 will be introduced to several new products, technologies, and services. Among the new technologies exhibited at the show will be:

Torrent M Series: automated ultrasonic aqueous cleaning systems for high precision Medical and Pharmaceutical cleaning applications. The Torrent is a single chamber, front loading rotary basket style machine that features 640 watts of Blackstone-NEY single or multi-frequency Ultrasonics for vacuum and non-vacuum immersion wash or rinse, basket rotation with user selected speed, direction and short cyclic modes, compressed air blow off, spray rinsing and hot air dry or vacuum dry with hot air assist.

The Torrent M Series machines are self-contained, skid mounted machines designed for both single pass and multiple pass chemistries utilizing onboard reservoirs while reducing water consumption through a broad range of user defined machine operation parameters.

English

English Spanish

Spanish Chinese

Chinese Canada

Canada Mexico

Mexico United Kingdom

United Kingdom