- Log in to post comments

Ransohoff, is proud to introduce its new generation Lean-Jet™ RT-18 robotically tended cellular parts washer. Ransohoff has developed an innovative, patent pending drive system that adds an entirely new level of flexibility to this already extremely effective cellular design. While the previous generation did provide planetary part rotation at each processing station, the new design allows for each individual table to be programmed to rotate a part in multiple directions, at varying speeds, or to pause and position a part for dedicated spaying or probing of critical holes or difficult to address areas. As table position is tracked throughout the cycle and parts are positively located at the load and unload station, this design is a perfect match for a robotically tended manufacturing cell.

Ransohoff, is proud to introduce its new generation Lean-Jet™ RT-18 robotically tended cellular parts washer. Ransohoff has developed an innovative, patent pending drive system that adds an entirely new level of flexibility to this already extremely effective cellular design. While the previous generation did provide planetary part rotation at each processing station, the new design allows for each individual table to be programmed to rotate a part in multiple directions, at varying speeds, or to pause and position a part for dedicated spaying or probing of critical holes or difficult to address areas. As table position is tracked throughout the cycle and parts are positively located at the load and unload station, this design is a perfect match for a robotically tended manufacturing cell.

- Log in to post comments

Come get a first-hand look at our innovative industrial and precision cleaning technologies and talk to our sales team about your cleaning solutions.

MRO Americas 2014 - (Phoenix AZ, USA) April 8 - 10 Booth 2602 MDM East – (New York, NY, USA) June 10 – 12 Booth 1882 SEMICON West – (San Francisco, CA , USA) July 8 – 10 Booth 2342 EASTPO 2014 – (Shanghai, China) July 14 – 17 IMTS 2014 – (Chicago, IL USA) September 8 – 13 Booth 5663 C-Touch – (Shenzhen, China) November 25 - 27- Log in to post comments

The AGI-SONIC, is a robust ultrasonic cleaning machine designed for heavy duty parts washing with vertical parts agitation. Constructed of all stainless steel and available in three standard sizes, each system incorporates an air powered agitation platform that agitates parts with a 6" stroke up to 15 times per minute. The AGI-SONIC parts washer includes automatic filling and liquid makeup (from a customer supplied source), pump and single bag filter, and an overflow weir skimmer and automatic oil removal system, and a lift-off lid. Ultrasonic time, cleaning tank temperature warm up, filtration and oil removal are all digitally controlled using a friendly touch pad interface. Completely self-contained and requiring a three phase power supply hookup, the largest machine can accommodate a platform load up to 500lbs. Learn more

The AGI-SONIC, is a robust ultrasonic cleaning machine designed for heavy duty parts washing with vertical parts agitation. Constructed of all stainless steel and available in three standard sizes, each system incorporates an air powered agitation platform that agitates parts with a 6" stroke up to 15 times per minute. The AGI-SONIC parts washer includes automatic filling and liquid makeup (from a customer supplied source), pump and single bag filter, and an overflow weir skimmer and automatic oil removal system, and a lift-off lid. Ultrasonic time, cleaning tank temperature warm up, filtration and oil removal are all digitally controlled using a friendly touch pad interface. Completely self-contained and requiring a three phase power supply hookup, the largest machine can accommodate a platform load up to 500lbs. Learn more

- Log in to post comments

- Log in to post comments

- Log in to post comments

- Log in to post comments

- Log in to post comments

Milton Svetanics has joined Cleaning Technologies Group, LLC as a Blackstone-NEY Ultrasonics Regional Sales Manager, effective November 2013 “Milton comes to us with not only the ambition and drive that our growing organization desires but also with a solid background in technical international sales. Milton is also fluent in Japanese which will certainly help us open some new doors for both Blackstone-NEY and Ransohoff" - Chris Whittaker, VP of Sales & Marketing CTG, LLC Milton is an experienced Account Executive with a technical background, along with a very successful sales record. Mr. Svetanics will focus his efforts on expanding our current industrial and geographic market presence for the Blackstone-NEY Ultrasonics product line.

Milton Svetanics has joined Cleaning Technologies Group, LLC as a Blackstone-NEY Ultrasonics Regional Sales Manager, effective November 2013 “Milton comes to us with not only the ambition and drive that our growing organization desires but also with a solid background in technical international sales. Milton is also fluent in Japanese which will certainly help us open some new doors for both Blackstone-NEY and Ransohoff" - Chris Whittaker, VP of Sales & Marketing CTG, LLC Milton is an experienced Account Executive with a technical background, along with a very successful sales record. Mr. Svetanics will focus his efforts on expanding our current industrial and geographic market presence for the Blackstone-NEY Ultrasonics product line.

- Log in to post comments

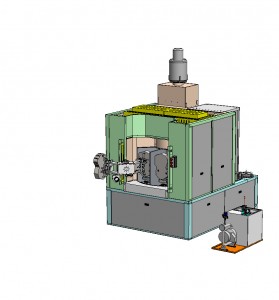

Ransohoff, is proud to introduce its new generation Lean-Jet™ RT-18 robotically tended cellular parts washer. Ransohoff has developed an innovative, patent pending drive system that adds an entirely new level of flexibility to this already extremely effective cellular design. While the previous generation did provide planetary part rotation at each processing station, the new design allows for each individual table to be programed to rotate a part in multiple directions, at varying speeds, or to pause and position a part for dedicated spaying or probing of critical holes or difficult to address areas. As table position is tracked throughout the cycle and parts are positively located at the load and unload station, this design is a perfect match for a robotically tended manufacturing cell. This cellular washer is available with various configurations offering not only the ability to wash and dry your parts but also rinsing or part cooling if necessary. The RT-18 accommodates a wide range of part sizes, weights and geometries and will produce up to one part, or table of parts, every 30 seconds depending on the application. The new generation Lean-Jet™ RT-18 is available with an Allen Bradley or Siemens PLC and HMI package.

Ransohoff, is proud to introduce its new generation Lean-Jet™ RT-18 robotically tended cellular parts washer. Ransohoff has developed an innovative, patent pending drive system that adds an entirely new level of flexibility to this already extremely effective cellular design. While the previous generation did provide planetary part rotation at each processing station, the new design allows for each individual table to be programed to rotate a part in multiple directions, at varying speeds, or to pause and position a part for dedicated spaying or probing of critical holes or difficult to address areas. As table position is tracked throughout the cycle and parts are positively located at the load and unload station, this design is a perfect match for a robotically tended manufacturing cell. This cellular washer is available with various configurations offering not only the ability to wash and dry your parts but also rinsing or part cooling if necessary. The RT-18 accommodates a wide range of part sizes, weights and geometries and will produce up to one part, or table of parts, every 30 seconds depending on the application. The new generation Lean-Jet™ RT-18 is available with an Allen Bradley or Siemens PLC and HMI package.

English

English Spanish

Spanish Chinese

Chinese Canada

Canada Mexico

Mexico United Kingdom

United Kingdom