- Log in to post comments

A couple of weeks ago CTG wrapped up a very successful EASTEC 2013 show. The SME reported that the attendance was 12,560 for the three days. This is up 16% from EASTEC 2011. The event drew attendees from 43 states across the country. CTG displayed the PROHT Sonic Tank with Ultrasonic Technology in the booth and our sales team met with many visitors to discuss our complete product line and cleaning solutions that we can provide  Thanks to those of you who came out to visit the CTG booth and we look forward to helping you with your cleaning solutions.

Thanks to those of you who came out to visit the CTG booth and we look forward to helping you with your cleaning solutions.

- Log in to post comments

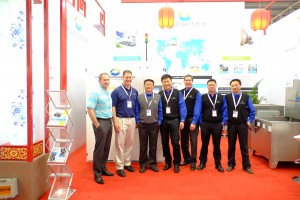

The 2013 China International Machine Tool Show (CIMT), sponsored and organized by China Machine Tool & Tool Builders' Association (CMTBA), took place from 22nd to 27th April in Beijing, China. It is the largest and most influential machine tool show in China, and is recognized as one of the four largest international machine tool shows in the world. More than 1200 exhibitors took part in the 13th CIMT which welcomed more than 265,600 visitors from manufacturing industries. CTG displayed the new LeanJet RB-2 Gen 3 Aqueous Immersion Cleaning System, AgiSonic Ultrasonic Parts Washer and the GMC Series GMC 1818 multiSONIKT2 generator, featuring Blackstone~NEY Ultrasonics' patented dual sweep technology, can operate at frequencies of 40, 80, 120, 140, 170, 220 and 270 kHz.

Thank you to all who visited the CTG booth at CIMT 2013, and we look forward to working with you on your parts cleaning needs. Visit our Facebook page to view more photos.

- Log in to post comments

Cleaning Technologies Group is pleased to announce that Mr. Liu Hong (Hunter) has join CTG Asia as Engineering Manager. Mr. Liu has nearly 10 years working experience in the parts cleaning industry as mechanical engineer, engineering manager, BU manager, and new market business development manager for two known washing machine companies from Europe.

Cleaning Technologies Group is pleased to announce that Mr. Liu Hong (Hunter) has join CTG Asia as Engineering Manager. Mr. Liu has nearly 10 years working experience in the parts cleaning industry as mechanical engineer, engineering manager, BU manager, and new market business development manager for two known washing machine companies from Europe.

- Log in to post comments

CleanVeyor Ultrasonic parts washer utilizes a combination of spray, immersion, and ultrasonic cleaning technologies and has proven successful in achieving Six Sigma consistency in a number of applications requiring high production outputs and tight cleanliness levels. Parts with complex and internal geometries that need final cleaning prior to assembly are ideal candidates. This cleaning process has proven to significantly reduce or eliminate warranty related failures that would be attributed to inadequate part cleaning. The CleanVeyor is modular so that more stages can be added as needed. For more information click here

CleanVeyor Ultrasonic parts washer utilizes a combination of spray, immersion, and ultrasonic cleaning technologies and has proven successful in achieving Six Sigma consistency in a number of applications requiring high production outputs and tight cleanliness levels. Parts with complex and internal geometries that need final cleaning prior to assembly are ideal candidates. This cleaning process has proven to significantly reduce or eliminate warranty related failures that would be attributed to inadequate part cleaning. The CleanVeyor is modular so that more stages can be added as needed. For more information click here

- Log in to post comments

The Parts Cleaning Expo (PCx) and the Precision Machining Technology Show (PMTS) is a Co-Locating Event that promotes the latest advances in cleaning equipment, chemicals and services, alongside machine tool builders, cutting tool companies, and software vendors that was held April 16 – 18. CTG displayed the PROHT Sonic Tank with Ultrasonic Technology in the booth and our sales team met with many visitors to discuss our complete product line and cleaning solutions that we can provide. We sincerely thank you for visiting us at the PCx show, and look forward to helping you to find the right cleaning solutions for your applications.

The Parts Cleaning Expo (PCx) and the Precision Machining Technology Show (PMTS) is a Co-Locating Event that promotes the latest advances in cleaning equipment, chemicals and services, alongside machine tool builders, cutting tool companies, and software vendors that was held April 16 – 18. CTG displayed the PROHT Sonic Tank with Ultrasonic Technology in the booth and our sales team met with many visitors to discuss our complete product line and cleaning solutions that we can provide. We sincerely thank you for visiting us at the PCx show, and look forward to helping you to find the right cleaning solutions for your applications.

- Log in to post comments

Cleaning Technologies Group a world leader in providing cleaning and waste minimization technologies will introduce a host of advanced cleaning solutions at the EASTEC 2013 in West Springfield, MA, May 14 - 16, 2013. Visitors to Cleaning Technologies Group Booth #3342 will be introduced to a number of new products, technologies and services. Among the new technologies exhibited at the show will be:

Cleaning Technologies Group a world leader in providing cleaning and waste minimization technologies will introduce a host of advanced cleaning solutions at the EASTEC 2013 in West Springfield, MA, May 14 - 16, 2013. Visitors to Cleaning Technologies Group Booth #3342 will be introduced to a number of new products, technologies and services. Among the new technologies exhibited at the show will be:  • PROHT Sonic Tank also known as the “Benchtop Series” is an entry-level benchtop ultrasonic cleaning system made of all stainless steel construction. Available in various sizes and intended to sit easily on a workbench or as a drop-in, these parts washers offer the same cleaning capabilities as the more elaborate models but at a lower price. They are great for cleaning small parts on an intermittent to semi-production basis but are not recommended for high volume cleaning. These tanks are available for use with single or multi-frequency generators. At the show we will have technical experts available to explain our technologies in more depth and provide suggestions to our customers to improve their cleaning processes.

• PROHT Sonic Tank also known as the “Benchtop Series” is an entry-level benchtop ultrasonic cleaning system made of all stainless steel construction. Available in various sizes and intended to sit easily on a workbench or as a drop-in, these parts washers offer the same cleaning capabilities as the more elaborate models but at a lower price. They are great for cleaning small parts on an intermittent to semi-production basis but are not recommended for high volume cleaning. These tanks are available for use with single or multi-frequency generators. At the show we will have technical experts available to explain our technologies in more depth and provide suggestions to our customers to improve their cleaning processes.

- Log in to post comments

- Log in to post comments

Cleaning Technologies Group a world leader in providing cleaning and waste minimization technologies will introduce a host of advanced cleaning solutions at the China International Machine Tool Show (CIMT)in Beijing, China April 22 - 27, 2013. Visitors to Cleaning Technologies Group Booth #W1-212 will be introduced to a number of new products, technologies and services. Among the new technologies exhibited at the show will be:  • New Gen 3 LeanJet RB-2 Aqueous Immersion Cleaning System uses a patented washing and rinsing process of agitation, spray impingement, hydraulic purging through immersion and rotation, ultrasonics, and heated blow-off drying. The patented "triple action" batch cleaning process was developed specifically to process a broad range of challenging parts, especially those with internal bores and passages and complex geometries, making this system capable of meeting critical cleaning expectations. The LeanJet RB-2 parts washer also features the latest Siemens programmable controller and operator interface screen. This controls platform boosts system flexibility for automation integration, process control and data logging while offering an intuitive user interface.

• New Gen 3 LeanJet RB-2 Aqueous Immersion Cleaning System uses a patented washing and rinsing process of agitation, spray impingement, hydraulic purging through immersion and rotation, ultrasonics, and heated blow-off drying. The patented "triple action" batch cleaning process was developed specifically to process a broad range of challenging parts, especially those with internal bores and passages and complex geometries, making this system capable of meeting critical cleaning expectations. The LeanJet RB-2 parts washer also features the latest Siemens programmable controller and operator interface screen. This controls platform boosts system flexibility for automation integration, process control and data logging while offering an intuitive user interface.

- Log in to post comments

Cleaning Technologies Group a world leader in providing cleaning and waste minimization technologies will introduce a host of advanced cleaning solutions at the PMTS / PCx 2013 in Columbus Ohio April 16 - 18, 2013. Visitors to Cleaning Technologies Group Booth #1325 will be introduced to a number of new products, technologies and services. Among the new technologies exhibited at the show will be: • Ultrasonic LeanVeyor Immersion Cleaning System utilizes a combination of spray, immersion, and ultrasonic cleaning technologies and has proven successful in achieving Six Sigma consistency in a number of applications requiring high production outputs and tight cleanliness levels. Parts with complex and internal geometries that need final cleaning prior to assembly are ideal candidates. The first process in this powerful combination is a spray wash using mechanical impingement to quickly remove gross levels of contamination from parts. Higher pressures can be used to remove greater amounts of debris. After scouring the external surfaces of the parts, the second process uses ultrasonic technology and is done in an immersion environment. The mechanical cleaning component of ultrasonics is the cavitation effect. Among nature’s most dramatic amplifiers of energy density, cavitation generates extreme local temperatures and pressures.

Cleaning Technologies Group a world leader in providing cleaning and waste minimization technologies will introduce a host of advanced cleaning solutions at the PMTS / PCx 2013 in Columbus Ohio April 16 - 18, 2013. Visitors to Cleaning Technologies Group Booth #1325 will be introduced to a number of new products, technologies and services. Among the new technologies exhibited at the show will be: • Ultrasonic LeanVeyor Immersion Cleaning System utilizes a combination of spray, immersion, and ultrasonic cleaning technologies and has proven successful in achieving Six Sigma consistency in a number of applications requiring high production outputs and tight cleanliness levels. Parts with complex and internal geometries that need final cleaning prior to assembly are ideal candidates. The first process in this powerful combination is a spray wash using mechanical impingement to quickly remove gross levels of contamination from parts. Higher pressures can be used to remove greater amounts of debris. After scouring the external surfaces of the parts, the second process uses ultrasonic technology and is done in an immersion environment. The mechanical cleaning component of ultrasonics is the cavitation effect. Among nature’s most dramatic amplifiers of energy density, cavitation generates extreme local temperatures and pressures.

- Log in to post comments

CTG would like to congratulate five employees who celebrated anniversaries. There is no substitute for the dedication and enthusiasm of our employees, and we greatly appreciate their many years of service to the company. Congratulations to Jim Prall with 35 years of service, Judy Hoffman Creech, Rob Crowe, Tom Keith with 20 years of service and Gary Shivley with 15 years of service. Thank you for your years of service and contributions you have made to the CTG family.

English

English Spanish

Spanish Chinese

Chinese Canada

Canada Mexico

Mexico United Kingdom

United Kingdom