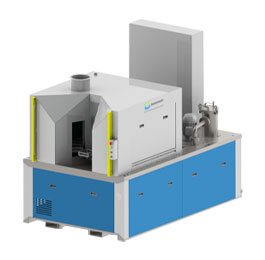

Ransohoff has developed and innovated a wide breadth of aqueous industrial parts washers, from small spray cabinets to large industrial parts washers, over the last 100 years. Cleaning platforms are reviewed on a regular basis with our sales and production teams as well as with our existing customer base to define the future updates that will provide the most parts cleaning value to our industrial customers. Our Innovation Engineering department is also working to stay ahead of the curve in developing the industrial parts washers our customers will need, not only tomorrow, but five to ten years from now.

The experienced CTG team is fully equipped to assist you in the selection of your industrial parts washer. Our knowledgeable experts will guide you in determining which parts cleaning system will most effectively and efficiently meet your needs based on factors such as:

- Soils/contaminants involved

- Parts materials

- Size and complexity of parts

- Volume of parts

- Process steps involved

- Automatic or manual handling

Whether you need a small spray cabinet or large industrial parts washer, CTG offers a wide range of industrial parts washer options to meet virtually any manufacturing and process requirement. We are proud to serve the parts cleaning needs of customers in a variety of industries. Contact us today to discuss your industrial parts cleaning needs.

What parts cleaning equipment is right for your needs?

Get help with our new guide

Planning for New Cleaning Equipment

Want to increase efficiency and improve quality of your parts cleaning?

Get help with our new guide

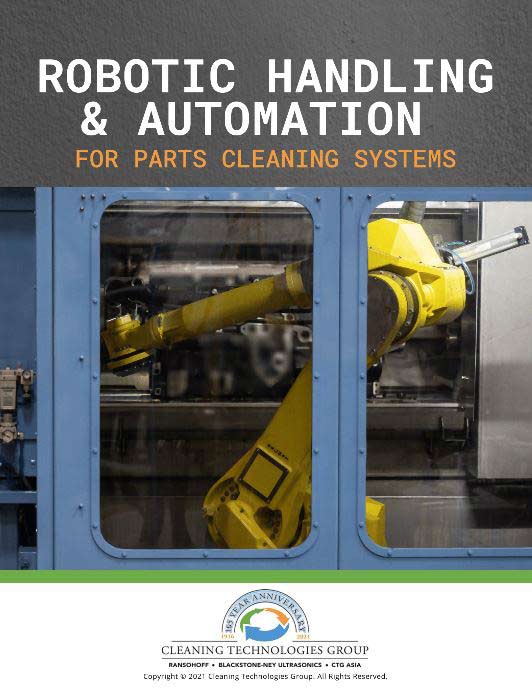

Robotic Handling & Automation

English

English Spanish

Spanish Chinese

Chinese Canada

Canada Mexico

Mexico United Kingdom

United Kingdom