Medical Design & Manufacturing (MD&M) West 2019 is scheduled to take place February 5 - 7, 2019 in Anaheim, California. MD&M West is the place for professionals in the global medical manufacturing community to learn about the latest advances in the medtech industry. In addition to more than 1,900 suppliers showcasing the latest solutions in contract manufacturing, manufacturing equipment, automation, R&D, medical device components, materials, plastics, and more, MD&M West hosts the largest three-day medtech conference in North America.

Medical Design & Manufacturing (MD&M) West 2019 is scheduled to take place February 5 - 7, 2019 in Anaheim, California. MD&M West is the place for professionals in the global medical manufacturing community to learn about the latest advances in the medtech industry. In addition to more than 1,900 suppliers showcasing the latest solutions in contract manufacturing, manufacturing equipment, automation, R&D, medical device components, materials, plastics, and more, MD&M West hosts the largest three-day medtech conference in North America.

As a parts cleaning solutions supplier to the medtech industry, CTG is excited to be participating in this year’s event. Attendees who visit the Blackstone-NEY Ultrasonics Booth #1354 will learn about our products, technologies, and services. Among the new technologies exhibited will be:

The New Blackstone-NEY Ultrasonics Stainless Steel GMC Series Cleaning System

Ransohoff, a leading name in cleaning technology, will be featured in the upcoming SHOT Show Week Supplier Showcase, happening January 21 -22, 2019, in Las Vegas, NV. The SHOT Showcase is a dedicated event for suppliers to present products and solutions to shooting, hunting, and outdoor industry manufacturers. Producers of parts, components, and assemblies for the shooting sports or outdoor sporting market will have the opportunity see new Ransohoff drum cleaning systems tanks, as well as many other parts cleaning solutions.

Innovative cleaning solutions to be featured at SHOT Show in Ransohoff Booth S1720 include:

The ultrasonic cleaning process uses a combination of ultrasound and water and/or parts cleaning solvent to clean a wide variety of component parts and assemblies. Ultrasonic cleaning is especially effective for delicate or complex parts.

The ultrasonic cleaning process uses a combination of ultrasound and water and/or parts cleaning solvent to clean a wide variety of component parts and assemblies. Ultrasonic cleaning is especially effective for delicate or complex parts.

During the ultrasonic cleaning process cavitation bubbles induced by high frequency sound waves are used to agitate the parts cleaning liquid. The agitation releases contaminants adhering to substrates such as plastic, metal, glass, ceramics, and rubber. The ultrasonic cleaning process allows the cleaning solution to penetrate blind holes, cracks, and recesses is to thoroughly remove all traces of contamination tightly adhering or embedded onto solid surfaces.

While ultrasonic cleaning is highly effective, the issue of “ultrasonic shadowing” can impair the thoroughness of this type of cleaning. Ultrasonic shadowing occurs when the parts being cleaned are positioned in a manner that casts an “ultrasonic shadow” on some of the other parts. This shadow prevents covered parts from being effectively cleaned. Though ultrasonic shadowing is known to occur, it can be difficult to define and predict.

Unlike the shadow cast by a solid object illuminated by the sun or a lightbulb, an ultrasonic shadow is not distinct in shape. Ultrasonic shadows are more like the shadows cast by diffused light, like the sun shining on a cloudy day, where the darkened area is less distinctly defined.

Ransohoff Washmaster Cabinet Washers Offer Flexible, Cost-Efficient Solution

Ransohoff Washmaster Cabinet Washers Offer Flexible, Cost-Efficient Solution

Ransohoff, a division of Cleaning Technologies Group, offers a comprehensive standard line of cabinet washers, including our Washmaster line of cabinet washers.

Utilizing spray technology, Washmaster cabinet washers are efficiently used in a wide range of industries and require minimal engineering to suit your application needs. The Washmaster series provides a highly effective and extremely cost competitive cabinet-type parts washer solution.

Washmaster CW-23-R / CW-35-R

The CW-Series Washmaster rotary table spray washer is an ideal point of use cabinet washer. A a perfect solution where minimal space is available, the CW series is very robust in construction and offers a platform that is pre-engineered, cost competitive, and ready for delivery.

CTG will be exhibiting many innovative cleaning systems at the upcoming IMTS conference to be held in Chicago, Illinois. Among the technologies displayed will be the LeanVeyor® Conveyor Washer system. Unlike typical conveyor washers, which have a reputation for inefficiency, our LeanVeyor parts washer has been developed to be the most energy efficient, conveyor cleaning system available today.

CTG will be exhibiting many innovative cleaning systems at the upcoming IMTS conference to be held in Chicago, Illinois. Among the technologies displayed will be the LeanVeyor® Conveyor Washer system. Unlike typical conveyor washers, which have a reputation for inefficiency, our LeanVeyor parts washer has been developed to be the most energy efficient, conveyor cleaning system available today.

Developed specifically for lean manufacturing, the LeanVeyor requires minimal floor space while providing exceptional cleaning and drying performance. Using common sense approach to component choice and placement, the LeanVeyor offers quick and efficient access and servicing. All stages are insulated and compartmentalized with exhaust dampers that adjust individually, reducing system heat loss.

The entire unit has been engineered and fabricated to be flexible, durable, simple to use and easy to maintain.

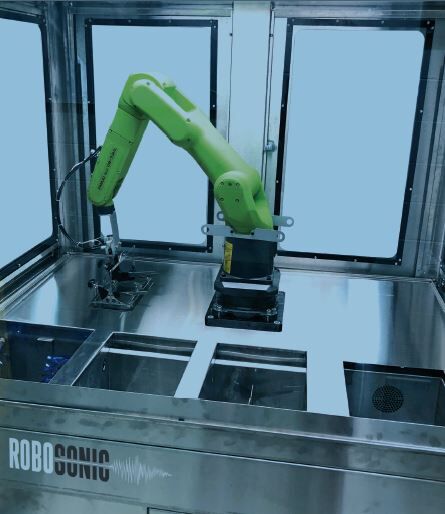

Blackstone-NEY Ultrasonics is excited to debut the newest of our many innovative cleaning technologies at the upcoming IMTS conference. Our exhibit will provide attendees with a first look at our new Robosonic Robotic Precision Cleaning Cell.

Blackstone-NEY Ultrasonics is excited to debut the newest of our many innovative cleaning technologies at the upcoming IMTS conference. Our exhibit will provide attendees with a first look at our new Robosonic Robotic Precision Cleaning Cell.

The Robosonic Cleaning Cell is a four-tank system that includes a spray wash, ultrasonic immersion wash, ultrasonic rinse tank and dryer. The robotic operation is provided by a Fanuc CR-7i. Fanuc is a trusted industry leader in robotic technology.

Robosonic features include:

CTG will be exhibiting a variety of innovative cleaning technologies at the upcoming IMTS conference to be held in Chicago, Illinois. The International Manufacturing Technology Show (IMTS), happening at McCormick Place, September 10 – 15th, is the premier manufacturing technology show in North America, bringing together buyers and sellers from 117 countries.

Among the systems displayed in the CTG booth will be our new Rotosonic™ Combination Spray and Ultrasonic Cleaning System. This automated ultrasonic cleaning system provides maximum cleaning efficiency through the use of high-pressure spray, part rotation, and ultrasonic energy. The Rotosonic will thoroughly clean heavily soiled parts in a one system, eliminating the need to purchase a spray cabinet and an ultrasonic machine separately. The Rotosonic provides the ultimate in flexibility in that it can either perform a single process or both processes, depending on your needs. The machine features a compact design, and eliminates the required labor and safety risks associated with moving parts from washer to washer.

Typical Applications:

Among the many innovative cleaning technologies CTG will be exhibiting at the upcoming IMTS conference will be our LeanJet® RB-2 Automated Immersion Cleaning System and our LeanJet® Cell-Jet.

Our LeanJet RB-2 Automated immersion cleaning system incorporates two (2) industrial standard size baskets of parts per cycle, cleaning up to twenty (20) baskets per hour. This system cleans parts by using a washing and rinsing process of agitation, spray impingement, hydraulic purging through immersion and rotation, ultrasonics, and heated blow-off drying. Engineered specifically to process a broad range of challenging parts, the "triple action" batch cleaning process is especially effective for cleaning parts with internal bores and passages and complex geometries. The LeanJet RB-2 is capable of meeting the most critical cleaning requirements. Customer specific basket designs are available to accommodate larger parts.

Our LeanJet RB-2 Automated immersion cleaning system incorporates two (2) industrial standard size baskets of parts per cycle, cleaning up to twenty (20) baskets per hour. This system cleans parts by using a washing and rinsing process of agitation, spray impingement, hydraulic purging through immersion and rotation, ultrasonics, and heated blow-off drying. Engineered specifically to process a broad range of challenging parts, the "triple action" batch cleaning process is especially effective for cleaning parts with internal bores and passages and complex geometries. The LeanJet RB-2 is capable of meeting the most critical cleaning requirements. Customer specific basket designs are available to accommodate larger parts.

CTG will be exhibiting many innovative cleaning technologies at the upcoming IMTS conference to be held in Chicago, Illinois. Among the systems displayed will be our Aquarius™ Series Multi-Tank Ultrasonic Cleaning Systems. This efficient high performance system combines ultrasonic cleaning with rinsing, drying, and other processing steps into a consolidated cleaning system to promote process integrity.

CTG will be exhibiting many innovative cleaning technologies at the upcoming IMTS conference to be held in Chicago, Illinois. Among the systems displayed will be our Aquarius™ Series Multi-Tank Ultrasonic Cleaning Systems. This efficient high performance system combines ultrasonic cleaning with rinsing, drying, and other processing steps into a consolidated cleaning system to promote process integrity.

This combination system features automated robotic transfer, environmental enclosure, and DI water system to increase cleanliness levels. This design also provides process consistency while significantly reducing the labor required for parts cleaning.

The cost-effective Aquarius Series Multi-tank Ultrasonic Cleaning Systems are pre-engineered to meet a variety of parts cleaning needs. This platform can also be employed to handle any nitric or citric acid passivation requirements.

Typical Applications:

When comparing parts cleaning equipment, you will most likely be looking at a number of factors including the amount of power offered by each system. In the case of ultrasonic cleaning equipment, more power does not necessarily mean the parts cleaner will provide more for your money.

When comparing parts cleaning equipment, you will most likely be looking at a number of factors including the amount of power offered by each system. In the case of ultrasonic cleaning equipment, more power does not necessarily mean the parts cleaner will provide more for your money.

In some cases, high-powered ultrasonic cleaning systems are needed to do a particular job, but more commonly an assumption is made that more energy is better when it actually is not. In order to understand why more power in an ultrasonic parts cleaning is not always advantageous, you must consider the design, as it relates to ultrasonic transducers and cleaning.

The ultrasonic devices used in an ultrasonic parts cleaner incorporate a number of individual vibrators attached to a plate or diaphragm. A liquid media is contained on the other side of the plate. When the vibrators activate the plate, the vibration produces sound waves in that liquid media. The vibrators depend on resonance at a certain frequency to deliver the required amplitude for vibration to create the cavitation and implosion in the liquid that does the cleaning. The individual vibrators are able to convert about 40 watts of electrical energy into mechanical energy as vibration.

English

English Spanish

Spanish Chinese

Chinese Canada

Canada Mexico

Mexico United Kingdom

United Kingdom