- Log in to post comments

Blackstone-NEY Ultrasonics is pleased to announce its newly redesigned Aquarius tank to tank precision ultrasonic cleaning system. Our patented technology allows us to incorporate seven (7) independent frequencies, 40-80-120-140-170-220-270, in a single tank which makes for a very compact design. Complete with a fully automated robotic transfer this high production cleaning system is designed to meet your most stringent cleanliness requirements. With the programmable controller being capable of running multiple recipes, dictated by an operator or part specific bar codes, this system is completely flexible for any part configuration. The controller can be programmed to track parts through the cleaning process as well as log all process parameter data points including dwell times, process temperatures, ultrasonic settings, and output this data for external storage. Ethernet connectivity is also standard in the Aquarius line allowing for full integration into any production environment. This system is designed to be modular and fully scalable allowing it to be used for a variety of final cleaning and Passivation processes for the Medical, Aerospace, and many other precision industries.

- Log in to post comments

The Cleaning Technologies Group's facility in Suzhou, China has recently expanded its production of parts washers to include Blackstone-NEY's Agi-Sonic and the NEW Lean-Jet RB-8 to its product line. The machines are being engineered and built by CTG employees in Suzhou to be sold directly to the Asian Marketplace, using the same quality standards and specifications we use here in the US. CTG Asia has been in operation and growing since 2007 and 2011 promises to be very exciting, as CTG continues its global commitment to being a worldwide provider of all your cleaning needs. Learn more about CTG Asia...

- Log in to post comments

The Cleaning Technologies Group, LLC is pleased to introduce the all new CH Series, a single tank ultrasonic cleaning console.  The CH freestanding ultrasonic cleaning console made of all stainless steel and recently re-designed with an operator friendly ergonomically located front panel, is ideal for a variety of manufacturing applications from single operator work cells all the way up to high throughput process lines. Availabe in a variety of standard sizes and a platform load up to 125lbs. with optional features like pump and filter, surface sparging, and timed controls, the all new CH is a must have from the cleanest of clean rooms to dirty shop floors where precision cleaning is needed.

The CH freestanding ultrasonic cleaning console made of all stainless steel and recently re-designed with an operator friendly ergonomically located front panel, is ideal for a variety of manufacturing applications from single operator work cells all the way up to high throughput process lines. Availabe in a variety of standard sizes and a platform load up to 125lbs. with optional features like pump and filter, surface sparging, and timed controls, the all new CH is a must have from the cleanest of clean rooms to dirty shop floors where precision cleaning is needed.

- Log in to post comments

2010 has been a very busy year for the Cleaning Technologies Group, LLC. From Shanghai to Chicago and a few places in between, CTG has been dedicated to bringing the latest advances in industrial parts cleaning directly to our customers. Most recently at IMTS thousands witnessed the debut of the new Lean-Jet Automated RB-2. The six day show was attended by over 80,000 visitors with 1,728 exhibitors displaying the latest in manufacturing technology. Being face to face with our customer's is so important. As we heard from many of you at the show, the manufacturing sector is starting to come back alive and CTG wants to help you plan for the future by offering the latest in cost effective cleaning solutions to your growing needs.  MEDTEC China 2010 was also a huge success for CTG. The show broke all previous records for attendees and exhibitors. MEDTEC is a great stage to reach out to our international clients in the medical manufacturing industry. Next year promises to be even busier for CTG, stay tuned for our upcoming 2011 trade show schedule...

MEDTEC China 2010 was also a huge success for CTG. The show broke all previous records for attendees and exhibitors. MEDTEC is a great stage to reach out to our international clients in the medical manufacturing industry. Next year promises to be even busier for CTG, stay tuned for our upcoming 2011 trade show schedule...

- Log in to post comments

Sept. 2010 - The Cleaning Technologies Group, LLC would like to congratulate the following employees on their years of dedicated service. CTG takes great pride in the quality of our workforce and it shows in CTG's years of experience in the industry. Thank you for your continued support to the success of the CTG family. 5 years - Kelly Haight, Jeff Spengler 10 years - Andrew Graham, Ken Hammond, Gene Phaneuf, Steve Stivers, Dan Stratton, Chris Whittaker 15 years - Tammy George, Ricky Pratt, Don Volpe 20 years - Darcy Cramer 30 years - Chris Ritze

- Log in to post comments

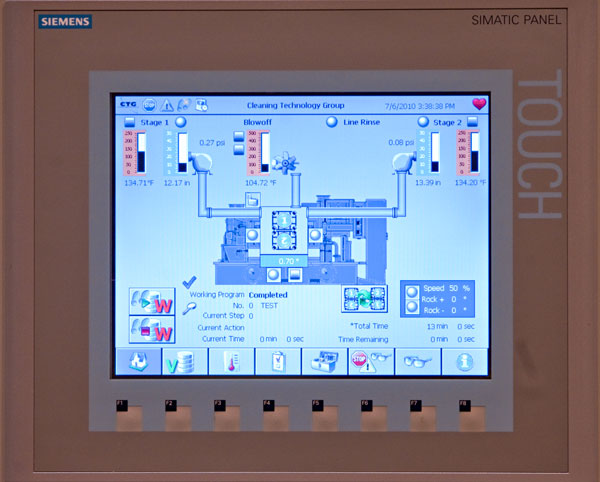

The Cleaning Technologies Group, LLC has partnered with Siemens to enhance our Lean product line with Siemens latest S7-1200 controls package. This new controller provides more efficient production flexibility, multi-lingual displays, a built in ethernet port, and full automation capabilities, all without increasing costs. This new controls package adds more analog and real time data capabilities to our parts washers, and more information means tighter process control for our customers. CTG consistently strives for continuous improvements and this venture with Siemens allows CTG to provide our customers with the latest technology at a tremendous value. For more information on the S7-1200 controller and its integration into CTG's Lean product line, read the full article in the latest edition of Control Design Magazine.

- Log in to post comments

Suzhou, China - Did you know the Cleaning Technologies Group, LLC facility in Suzhou, China has a fully operational technical center Our analytical laboratory can conduct cleaning trials to simulate part cleaning within a production environment to develop and optimize the ideal part specific cleaning levels. CTG can develop a cleaning process to meet cleanliness specifications that apply to just about any industry, meeting even the most stringent ultrasonic cleaning requirements. Our facility may be new, but CTG has over 90 years of experience in the parts cleaning industry. Request a lab test today and see for yourself what our technical center has to offer.

- Log in to post comments

Did you know that Blackstone-NEY Ultrasonics was an industry pioneer in the development of ultrasonic cleaning technology? Currently holding twelve major patents for designs ranging from multiple frequency transducers (universal transducers) and multiple frequency producing generators (multiSONIK), to generators that produce sweeping frequencies (sweepSONIK). Download our milestone list here! Today these patented technologies, especially the multi-frequency universal transducers and generators, are an extremely important part of the Cleaning Technologies Group product offering. They are used in standard units such as our CH tank and the PROHT tank as well as in elaborate Aquarius tank to tank cleaning and passivation systems. Industry use ranges from the medical implant arena to optics and semiconductor wafer cleaning.

multiSONIK Generator

sweepSONIK Generator

- Log in to post comments

Cincinnati, OH - The Cleaning Technologies Group was recently awarded the Extraordinary Member Award from TechSolve for their leadership and service to improving manufacturing processes in today's changing business environment. Jim McEachen - President of CTG, recently attended "Hill Day" in Washington DC to meet with Senators and Representatives as part of the Manufacturing Extensions Partnership, a federal program that focuses on helping small and mid-size manufacturing businesses improve their processes and competitive edge. CTG has been a member of TechSolve since 1998 and is committed to improving manufacturing standards not only in the industrial parts cleaning sector but overall to better serve our customers, employees, and surrounding community partners.

- Log in to post comments

Nashville, TN - CTG continually strives to improve our customer service. Recently Joe Servizzi, Customer Satisfaction Service Manager for CTG attended the 40th annual AMT Customer Service Conference in Nashville, TN. The event focused on what constitutes leadership in customer service, powerful networking opportunities, and the future of human resources in the workplace. "The AMT Service Conference was a great networking opportunity and allowed me to share ideas with my peers in the service industry to better serve our customers. The interactive activities were a good refresher course for dealing with customers and employees in general, but ultimately zeroed in on dealing and communicating with the younger generation of engineers and maintenance technicians, both internally & externally." - Joe Servizzi

Nashville, TN - CTG continually strives to improve our customer service. Recently Joe Servizzi, Customer Satisfaction Service Manager for CTG attended the 40th annual AMT Customer Service Conference in Nashville, TN. The event focused on what constitutes leadership in customer service, powerful networking opportunities, and the future of human resources in the workplace. "The AMT Service Conference was a great networking opportunity and allowed me to share ideas with my peers in the service industry to better serve our customers. The interactive activities were a good refresher course for dealing with customers and employees in general, but ultimately zeroed in on dealing and communicating with the younger generation of engineers and maintenance technicians, both internally & externally." - Joe Servizzi

English

English Spanish

Spanish Chinese

Chinese Canada

Canada Mexico

Mexico United Kingdom

United Kingdom