Looking for ways to increase process efficiency and productivity? Automating your parts washing process is a great way to implement simple, but significant improvements.

If you have considered the idea of automated parts washing but thought it would be complicated or cost-prohibitive, now is the time to revisit the idea! CTG can do custom engineered solutions and has several highly flexible approaches to automating your parts washing process to realize significant cost savings and efficiency gains.

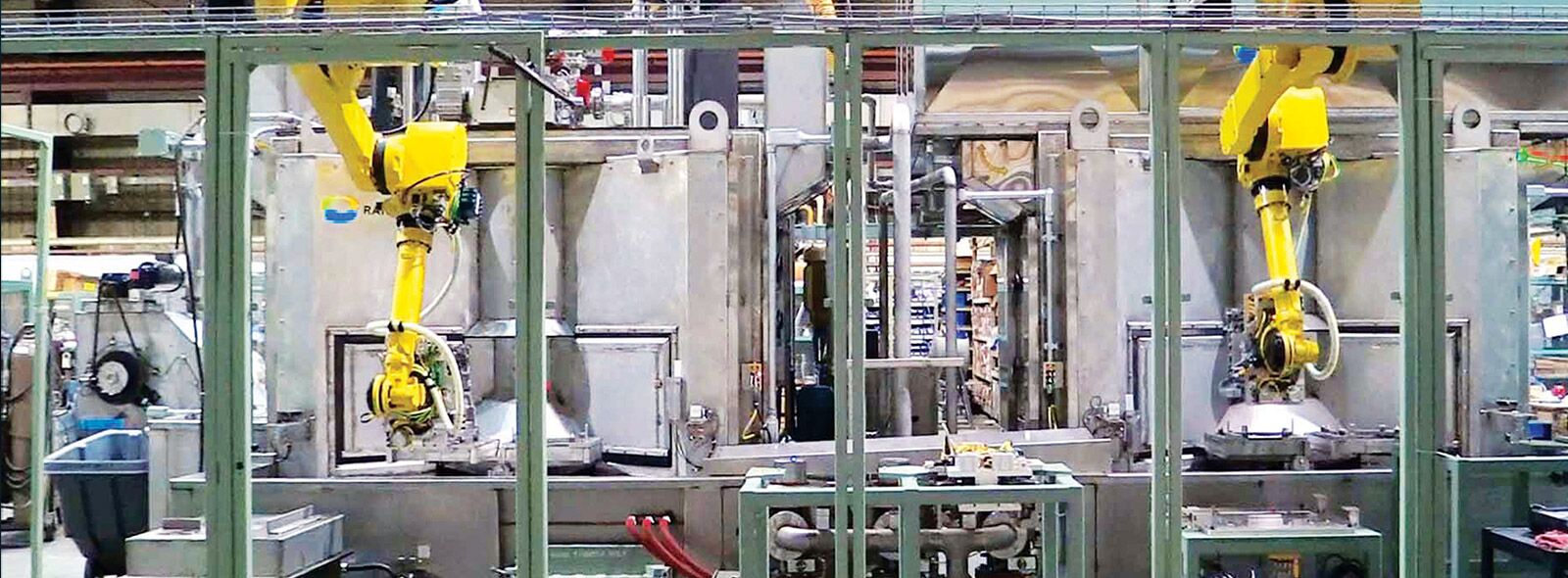

Robot Pick and Place

This set up would involve a part that is coming off of a process line, a machine center or off of a cueing pallet. The robot can be placed on the conveyor line or in the washer, where it will both position the part for washing and then place it into the next station in the process.

Tie Washer into a Flow Line

This option positions the washer within an automated flow line coming out of a machining center. Parts are automatically placed on a belt or other means of transport directly following an automated machining process. Robotic automation puts the parts in place for the next step in the process.

Parts Washing Nozzles on a Robot and Stationary Nozzles Designed to Work with Robots

Parts are loaded into a cabinet and robotic arms fitted with spray nozzles do the actual washing. This approach can provide high pressure spray washing, and washing in specific areas for precise cleaning. Systems can also be designed with stationary nozzles, allowing the robot to manipulate parts around them for cleaning.

Robosonic – The Robotic Automated Cleaning System

The Robosonic provides precision cleaning and maximum efficiency in a robotic automated cleaning cell. This four-tank system incorporates a spray wash, ultrasonic immersion wash, ultrasonic rinse tank and dryer. Cleanroom /cleanroom enclosure possibilities eliminate the need for personnel.

https://www.youtube.com/watch?v=jOVs9_4pj2s

TT-180 Ransobotic Washer

By combining extremely flexible robot-operated spray nozzles, precision worktable, and powerful controls and programmability, users now have optimum cleaning performance and efficiency for their increasingly demanding complex parts washing requirements.

Ransobotic Washer TT-180

https://www.youtube.com/watch?v=N4Xg3ahHprw

Ransohoff Modular RT-FLEX+

This innovative system that takes valuable time, manual effort, and cost out of the washing process, while adding flexibility to easily accommodate two unique engine designs simultaneously, as well as engine model, size and configuration changes as they occur in the future.

Modular RT Flex+ Video

While CTG can provide a complete automated parts washing system, we also offer automation options that are highly flexible, and can be designed to integrate with your existing parts washing process.

CTG is an authorized FANUC Robot integrator, but we have the ability to design a system to work with any type of robot. We are highly flexible in our automated parts washer design projects, whether you need assistance with purchasing a robot, or just need a parts washer set up that robot ready.

Automated parts washing systems can include ultrasonic cleaning, serving markets like medical and electronics, as well as spray washer systems, serving general manufacturing processes such as automotive.

Advantages of automating the parts washing process include:

- Faster parts cleaning

- Less manpower required

- High repeatability and fewer errors

- Small footprint, in many cases

- Easily modified for future products and processes.

Ready to learn more about automatic parts washer options? Contact us to discuss how automated parts cleaning can improve your operations!

English

English Spanish

Spanish Chinese

Chinese Canada

Canada Mexico

Mexico United Kingdom

United Kingdom