Introducing the perfect washer for high volume cleaning applications

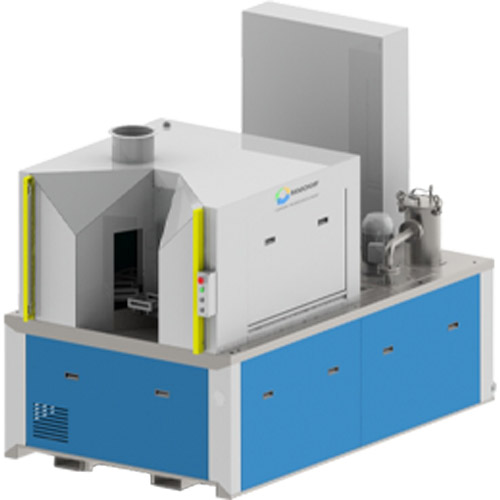

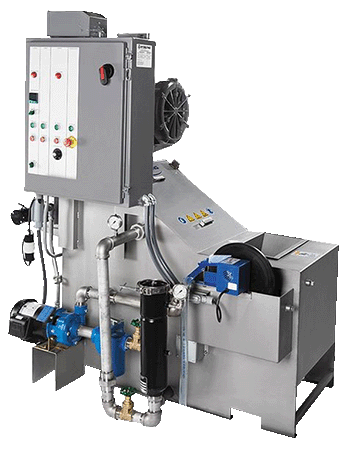

The RBS Modular System is an automated immersion cleaning system that can be expanded as needed to meet your process requirements. The RBS Modular System is a dedicated inline process that includes a Wash, Rinse, Ultrasonic Wash, Ultrasonic Rinse, Heated Blow Off and a final Vacuum Drying System. This system is set up to process parts in a basket or on a fixture. The RBS Modular System can handle parts up to 1100 LBS (500kg) and can do up to 15 cycles per hour.

The RBS Modular System cleans using a washing and rinsing process of agitation, spray impingement, hydraulic purging through immersion and rotation, ultrasonics, and heated blow-off drying. The "triple action" batch cleaning process was developed specifically to process a broad range of challenging parts, especially those with internal bores and passages and complex geometries, making this system capable of meeting critical cleaning expectations.

Read more

English

English Spanish

Spanish Chinese

Chinese Canada

Canada Mexico

Mexico United Kingdom

United Kingdom