Manufacturing processes have become more technologically driven as today’s systems and equipment have evolved to higher levels of sophistication. These advancements have meant less downtime and greater productivity with higher levels of precision and quality. The parts cleaning industry is keeping pace with this trend by offering cleaning equipment that provides enhanced features and sophisticated control technology.

This advancement in parts cleaning equipment can be seen in the newest generation of cleaning systems from Ransohoff and Blackstone-NEY Ultrasonics divisions of Cleaning Technologies Group. CTG is a global supplier of the most innovative industrial and precision cleaning technologies available today. CTG is a leading manufacturer of aqueous based parts cleaning systems including: spray, immersion, and ultrasonics, in both standard and custom designs, as well as a complete line of recyclable aqueous chemistries and waste minimization technologies.

Ransohoff and Blackstone-NEY Ultrasonics offer a wide range of technology-driven parts cleaning equipment. Examples include:

The LeanJet RT-18 has a planetary rotary table that allows a single point load and upload while ensuring 360 degree part coverage for cleaning and drying, as well as a patented triple action cleaning system.

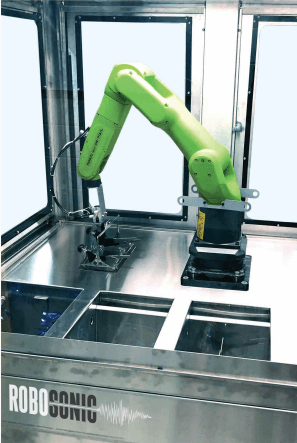

The Robosonic provides precision cleaning and maximum efficiency in a robotic automated cleaning cell. This four-tank system incorporates a spray wash, ultrasonic immersion wash, ultrasonic rinse tank and dryer.

The TT-180 Ransobotic Washer combines extremely flexible robot-operated spray nozzles, precision worktable, and powerful controls and programmability to deliver optimum cleaning performance and efficiency

CTG parts cleaning equipment has adopted automation, combined technologies and include more sophisticated filtration systems to help address critical areas. Systems also incorporate software technology that tracks parts, machine productivity, as well as faults and functions. The advanced controls even allow the manufacturer to work on equipment off site.

On the whole, the manufacturing industry has seen increasing use of robotics and automation. These technology-driven solutions are being incorporated into parts washing equipment to deliver highly effective and efficient cleaning solutions. This parts cleaning technology is particularly beneficial as parts become smaller and more complex, and as products and processes are subjected to extreme levels of scrutiny to ensure regulatory compliance.

Going along with compliance issues is the concern that consumer awareness is more highly focused on contamination and how it affects product quality and useful life span. This translates to a manufacturing demand for parts with tighter tolerances and better surface finishes, which means cleaning systems are playing a more critical role in parts production.

Contact CTG today to discuss your parts cleaning technology needs.

English

English Spanish

Spanish Chinese

Chinese Canada

Canada Mexico

Mexico United Kingdom

United Kingdom