Whether we are running appliances, charging phones or turning on lights, accessing electricity is a convenience we take for granted. As long as our devices do what they are expected to do, we do not give electricity a second thought beyond plugging into the outlet. It is, however, important to consider what happens behind the wall in terms of electricity. There can be significant variations in the connections, which may be of considerable importance when powering equipment such as parts washers.

Whether we are running appliances, charging phones or turning on lights, accessing electricity is a convenience we take for granted. As long as our devices do what they are expected to do, we do not give electricity a second thought beyond plugging into the outlet. It is, however, important to consider what happens behind the wall in terms of electricity. There can be significant variations in the connections, which may be of considerable importance when powering equipment such as parts washers.

Throughout most of North America the 120 volt outlet is the standard power configuration in homes and offices. Two parallel slots serve as electrical conductors and the rounded half-circle hole that is turned on its side is the ground. The larger of the two slots can also serve as the ground for some plug types, while the other is considered the hot side of the circuit. Both the ground slot and the D are at ground potential but are connected to the distribution box by separate wires.

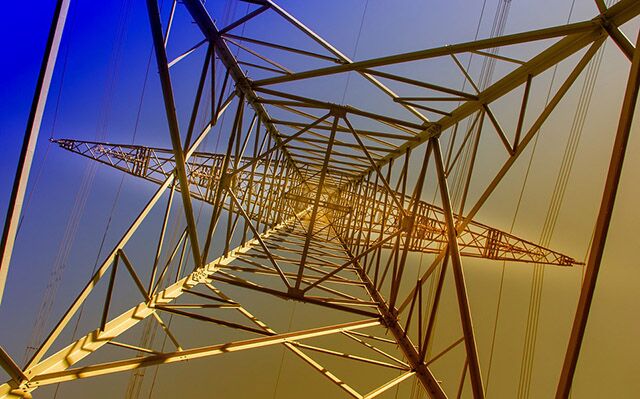

Prior to electricity making the journey from the power plant to a wall outlet, a transformer reduces the current down to what will be necessary to an individual home or office with the power it needs. Typically this amounts to 120/240 volts in a split phase configuration.

The voltage is reduced from the primary source down to 240 volts RMS in the secondary coil, which has a center tap connected to some form of solid ground. This provides two 120 volt RMS sources. Devices operating at 120 volts RMS, such as lamps and appliances, are connected to one of these two sources with fifty percent of the devices operating with alternating current that is 180 degrees out of phase with the others, hence the term split phase.

When it comes to items that use significant amounts of electricity, such as parts washing equipment, the differential between the two phases is used to provide a 240 volt RMS source. It is important to note that neither of the hot wires is ground in this situation, and devices operating from 240 volts are actually required to have a ground wire connected for safety purposes. Some hybrid devices utilize both 120 and 240 volts RMS and are required to have four wires, one connected to each side of the 240 volts RMS source, one connected to the ground of the transformer and another connected to the earth ground for safety.

As your knowledgeable and experienced source for parts cleaning equipment, CTG Technologies can help you with the installation of the right parts cleaning system to meet your needs, and to make sure it is powered up safely and efficiently.

English

English Spanish

Spanish Chinese

Chinese Canada

Canada Mexico

Mexico United Kingdom

United Kingdom