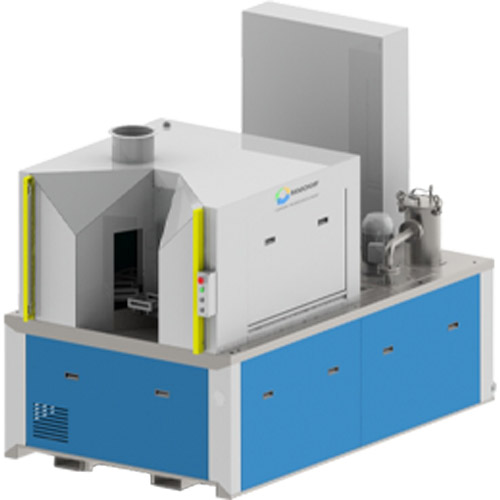

Ransohoff, a division of Cleaning Technologies Group, is pleased to announce the addition of the Cell-U-Clean line to our selection of aqueous parts washers. This new line has been specifically designed to be a compact and effective parts cleaning option for peak efficiency in cell manufacturing environments.

The Cell-U-Clean line was developed with a small footprint in mind. These washers feature single point load and unload to accommodate cell manufacturing configeraturations. Our Cell-U-Clean high-capacity cabinet washers are available in work envelopes ranging from 6” to 36”.

All products in the Cell-U-Clean line feature stainless steel construction and are built with standard off-the-shelf components to ensure long life and ease of maintenance. Our platform-based cabinet type parts washers require little engineering to fit your application, making them extremely cost competitive. They can be set up in a cell to be robot tended or manually loaded.

Cleaning Technologies Group employees lived fiercely and wore red to support the fight against heart disease back in February. Thank you to all who showed their spirit on #WearRedDay!

Cleaning Technologies Group has added a used machinery section to our website. Here customers will be able to find affordable, quick delivery equipment options to meet their current needs.

The CTG used machinery offering will include equipment from Blackstone-NEY Ultrasonics and Ransohoff that is built and ready to ship, allowing us to meet the needs of customers who require a quick parts washing solution. These machines will include new stock machines, demo and trade show models, as well as refurbished items. Our manufacturing capability and expertise enable us to provide refurbished machinery that delivers dependable performance and value.

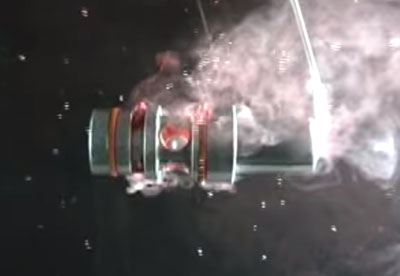

Valves and fittings are typically intricate and can be complex in design. They require precision cleaning to remove debris, oils, and other production materials. If valves and fittings are not thoroughly cleaned, their performance and reliability could be compromised in their intended applications.

Blackstone-NEY Ultrasonics develops commercial precision ultrasonic cleaning equipment that is well-suited for valve and fitting cleaning. Our ultrasonic cleaning technology is highly effective for removing dirt, grease and grime to meet ever-changing manufacturing and cleanliness specifications.

An important advantage of our ultrasonic cleaning systems is that they are designed for quick and easy setup. Our highly effective solutions let you improve your cleaning specifications and free your workforce to perform more productive tasks, providing you with a quick return on your investment. The ultrasonic cleaning process produces cavitation energy within the tank, which attacks the buildup of oils and residue from forging, machining and heat treatment.

The ultrasonic cavitation energy will effectively clean valves and fittings for the highest finish quality. This means effective cleaning as well as savings on time, labor and material costs.

Blackstone-NEY Ultrasonic systems are engineered for long life, durability, and excellent performance, while also being aqueous-based and environmentally safe.

Ransohoff, a division of Cleaning Technologies Group LLC, has introduced its LeanDrum CF Washer. This new platform provides an energy efficient, reliable solution for your high-volume cleaning needs, along with an innovated design for cold forming applications.

The LeanDrum CF features a very robust, lower cost option utilizing stainless steel tanks, drum and housing, premium electrical components, full immersion cleaning system and forced air dryer technology to produce consistently high quality cleaning results over an extended machine life. With this new design, you may recognize less chemical utilization and have better oil control resulting in a longer bath life. In this new design, you will have the ability to apply more aggressive chemicals without foaming. The new LeanDrum CF is designed for easy access that will allow easy drum removal for maintenance.

The Ransohoff LeanJet RB-8 Immersion Cleaning System was recently featured online and in the print edition of Production Machining. Ransohoff’s rotary basket washer is touted as a productivity-enhancing solution to a cleaning process bottle-neck.

The application focus in the story was developed for Allfast Fastening Systems, part of California-based TriMas Aerospace. The company, which produces components and installation tooling for the aerospace industry, was in need of an efficient parts cleaning solution to replace a highly cumbersome and labor-intensive cleaning process. The operation in this application involved the manual cleaning of up to 5,000 parts per day.

Cleaning Technologies Group and Blackstone-NEY Ultrasonics are leading names in the parts cleaning equipment and ultrasonic cleaning equipment industry. We offer solutions for every kind of parts cleaning application. Our advanced ultrasonic cleaning technology is highly effective for reliably removing the dirt, grease, and grime that are common for bicycle and scooter components.

Our precision ultrasonic cleaning solutions for bicycle, E-bike, and scooter components can be customized to work effectively and efficiently in any step of your manufacturing process. Deep cleaning can be done in much less time than would be needed for manual cleaning. The Ultrasonic tank and transducers produce cavitation energy that attacks buildup of grime on components, leaving them in pristine condition.

Typical Applications

- Chains

- Gears

- Cables

- Shifters

Blackstone-NEY Ultrasonic systems are built to commercial grade standards for long life, while also being aqueous-based and environmentally safe to operate.

David Holmes of D G Holmes Engineering LTD, dba RANSOHOFF in the UK, announced he will retire at the end of 2020. David Holmes has represented Ransohoff and Blackstone-NEY Ultrasonics in Europe for over twenty-three years.

“It is bittersweet when your long tenured people decide it is time to retire,” said Barney Bosse, CEO of Cleaning Technologies Group (CTG). “David Holmes has been with Ransohoff for decades leading our efforts in the UK and Europe. His dedication to the company has been outstanding, and David will be missed by his fellow co-workers and customers alike. We wish him all the best in retirement and many happy years with his family.”

Following the retirement of Mr. Holmes, Ransohoff UK will merge with Unitech Washing Systems, LTD in January of 2020. Colin Boocock who has had many years of involvement with CTG Group, will be heading up sales and support on all metal parts cleaning projects with Unitech Washing Systems.

Proper machine maintenance is an important factor in extending equipment life, decreasing downtime, and improving bottom line profitability. Ransohoff offers a highly effective tool for keeping equipment in peak operational condition with its line of Evercycle™ Machine Maintenance Products.

Evercycle machine maintenance product benefits include:

- Ability to operate at a wide range of temperatures and concentrations

- Low foaming characteristics

- Designed to dissolve and remove a wide range of contaminants that can affect machine performance

- Safe for use with most industrial washing equipment, including:

- Spray

- Immersion

- Ultrasonic

Evercycle products are formulated at a strength to restore your equipment to “like-new” operating condition within an 8-hour shift or less.

Evercycle Restore products fully restore your tanks, wash chambers, and pump screens to “like-new” condition.

An all-purpose machine restorer, Evercycle Restore features a unique blend of organic acid and soap designed to descale and degrease machines. It can be used for intermediate preventative maintenance treatments as well as deep cleaning maintenance for all types of parts washers. Depending on the operating concentration and temperature, Evercycle Restore can degrease, descale, de-rust, and brighten most washer and tank surfaces.

Ransohoff, a division of Cleaning Technologies Group, LLC is excited to announce our recent partnership with SurfacePrep. Established in 1956, SurfacePrep has been a leading distributor of surface enhancement solutions. The focus of Ransohoff's partnership with SurfacePrep will be on the distribution of Ransohoff industrial parts washers in the United States and Canada.

As a leading supplier of abrasive blasting media and abrasive finishing equipment, SurfacePrep has established a collection of the best on-site and local technical consultants whose knowledge of abrasive media and finishing equipment is unmatched in the field. SurfacePrep skilled sales team works closely with local manufacturers to develop the best possible solutions for every concern.

English

English Spanish

Spanish Chinese

Chinese Canada

Canada Mexico

Mexico United Kingdom

United Kingdom